flue gas analysis meaning|sorbothane temperature efficiency chart : manufacturers Carbon capture, utilization, and storage (CCUS) is expected to mitigate CO 2 emissions significantly since CO 2 is captured from the flue gas emitted by power and industrial processes and then either used in manufacturing processes or sequestrated into geographical formations. CO 2 capture is an energy-intensive process, and its energy consumption is . WEBEhen9999. Indonesia hot mami and chubby big ass doggystyle poked big dick. 3.1M 100% 4min - 360p. Hot Blonde Big Ass. 7.1k 82% 14sec - 360p.

{plog:ftitle_list}

Virgem Novinha Dando a Buceta Pela Primeira Vez. Virgem Novinha dando a buceta pela primeira vez – video de uma novinha gostosa que resolveu dar a bucetinha virgem e delirou gemendo e gritando alto enquanto o amigo mete forte na sua bucetinha apertada. Categorias Novinhas Virgens.

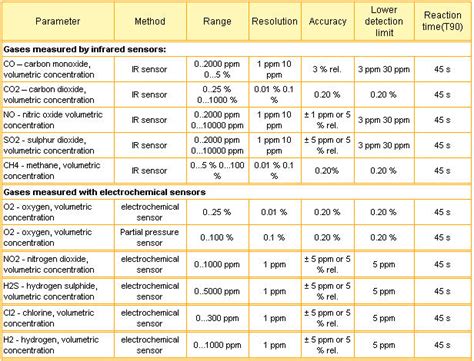

What Is Flue Gas Analysis? The term "flue" refers to the long pipes that are used to discharge exhaust gases, and are commonly found as chimneys, ducts, or simple pipes. The gases ejected by flues have a wide .Interpreting flue gas data helps optimize combustion processes and reduce harmful emissions. Key calculations include air-fuel ratios and excess air percentages, while environmental considerations focus on reducing greenhouse gases and other pollutants through various control technologies. Flue Gas Composition and Analysis Composition of flue gasesFlue gases released from the boiler chimney contain gases and particulate matter that pollute the environment. Continuous monitoring of stack emission is essential to ensure efficient boiler operations and adherence to environmental norms. . Both single-point and multi-point analysis options are available in the market. However, the use of . Flue gas, including both leftover O 2 and any unburned fuel, flows into the sensor. Given the high temperature and high surface area of the platinum beads (Figure 4), combustion of any unburned fuel and leftover O 2 is .

Carbon capture, utilization, and storage (CCUS) is expected to mitigate CO 2 emissions significantly since CO 2 is captured from the flue gas emitted by power and industrial processes and then either used in manufacturing processes or sequestrated into geographical formations. CO 2 capture is an energy-intensive process, and its energy consumption is .emissions and improve the safety of fuel burning equipment. Combustion analysis begins with the measurement of flue gas concentrations and gas temperature, and may include the measurement of draft pressure and soot level. To measure gas concentration, a probe is inserted into the exhaust flue and a gas sample drawn out. Ex-

The meaning of FLUE GAS is the mixture of gases resulting from combustion and other reactions in a furnace, passing off through the smoke flue, composed largely of nitrogen, carbon dioxide, carbon monoxide, water vapor, and often sulfur dioxide, and sometimes serving as a source from which carbon dioxide or other compounds are recovered.Flue gas treatment, a process designed to reduce the amount of pollutants emitted from the burning of fossil fuels at an industrial facility, a power plant, or another source. Flue gas—the emitted material produced when fossil fuels such as coal, oil, .When H 2 O vapours are included in the exhaust or flue gases, then the products of combustion are wet. When H 2 O vapours are excluded from the analysis, then the products of combustion are known as Dry Products of Combustion and in practice we consider the dry products of combustion. With the exclusion of the H 2 O vapours, the table will be slightly modified .ii) Flue gas oxygen content. iii) Flue gas carbon monoxide (CO) content. iv) Flue gas emissions content (NOx, if appropriate). (1) Additional flue gas component analysis is required when the environmental permit specifies limits on emission components. A common regulated emission component is nitrogen oxides (NOx). v) Emissions control settings.

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide (SO 2) . This revised standard (PTC 40-2017) covers Dry and Regenerable FGD systems and provides a more detailed Uncertainty Analysis section. This standard is currently in use today by companies around the world. As of June 1973, .Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, [1] or coal.According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle.It often disperses downwind in a pattern called an exhaust plume.Flue Gas Analysis as a Boiler Diagnostic Tool Overview, and Traditional Application Combustion flue gas analysis has been used by Power Plant Operators for decades as a method of optimizing fuel/air ratio. By measuring the amount of excess oxygen and/or CO in the flue gases resulting from combustion, plant operators can operate at the bestFlue gas (sometimes called exhaust gas or stack gas) is the gas that emanates from combustion plants and which contains the reaction products of fuel and combustion air and residual substances such as particulate matter (dust), sulfur oxides, nitrogen oxides, and carbon monoxide (Table 3.7). When burning coal and/or waste materials, hydrogen .

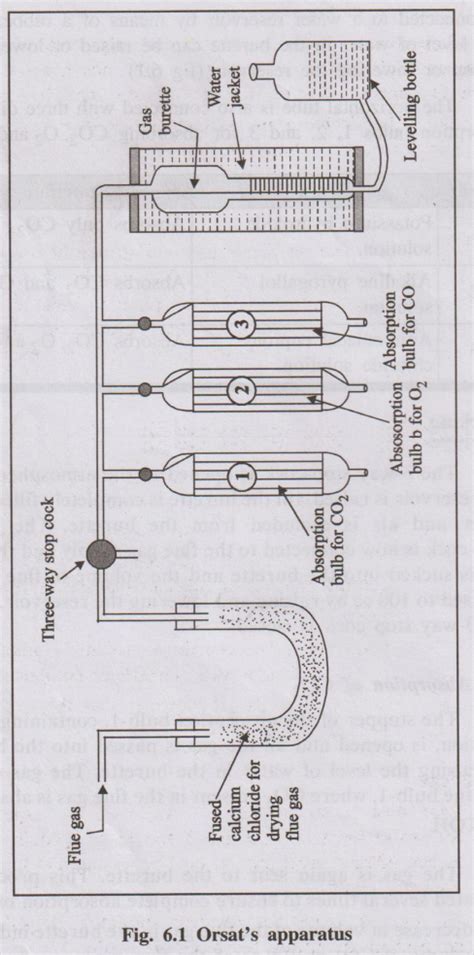

Significance (or) uses of flue gas analysis. 1. Flue gas analysis gives an idea about the complete or incomplete combustion process. 2. If the flue gases contain considerable amount of CO, it indicates that incomplete combustion is occuring and it .

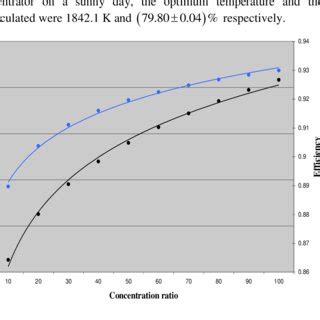

sorbothane temperature efficiency chart

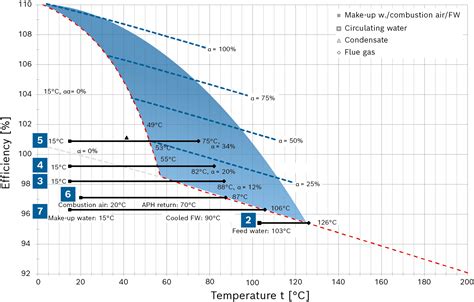

flue gas temperature chart

1.4.4 Gas volume, diluting effect, reference value 16 1.5 Flue gas (exhaust gas) and its composition 19 1.6 Gross calorific value, net calorific value, efficiency 23 1.7 Dew point, condensate 26 2. Gas analysis for industrial flue gases 29 2.1 Combustion optimization 31 2.2 Process control 34 2.2.1 Process heaters 34 EFFICIENT; The testo 310 co2 detector is ideal for more complex flue gas analyses, maintenance, safety checks, and furnace efficiency confirmations of residential heating systems VERSATILE; With its advanced .

Flue gas recirculation, or FGR, is the most effective method of reducing NOx emission from industrial boilers with inputs below 100 MMBtu/hr. FGR entails recirculating a portion of relatively cool exhaust gases back into the combustion process in order to lower the flame temperature and reduce NOx formation. It is currently the most effective .

Flue gas analysis using a Nova flue gas analyzer will enable you to measure the concentrations of pollutants present and adjust burners on a boiler for optimal combustion. Nova exhaust gas analyzers are useful for environmental control, for general boiler maintenance, and also as a tool for reducing fuel costs.Flue Gas Analyser with direct CO2 Measurement and CO sensor protection KANE LINK. CONTENTS Page No. 2.1 2.2 2.3 4.2 2 KANE458s MANUAL 2 1 3 GENERAL SAFETY 4.1 BATTERY TYPE 4 BATTERIES . 10 VIEWING FLUE GASES USING ROTARY DIAL 24 AUX SCREEN 10.1 24 02 / EFF SCREEN 10.2 25 .A flue gas analyzer is an appliance that operates flue gases for emissions and efficiency purposes and it may be an inexpensive hand-held instrument or a large unit that is permanently installed with a flue in manufacturing industries. The analyzer has an internal memory system that stores gas readings information until the real values are [.]

Flue gas analysis plays the three critical roles of (1) operational setpoint for “excess oxygen” to ensure adequate air (and air-fuel) ratio at the burner, (2) optimization mechanism to reduce fuel consumption and emissions caused by operating too high of an “excess air” level at the burner, and (3) safety monitoring to detect high .A flue gas analyser, also called an emissions analyser, or a stack analyser, is a specialized instrument used to measure the composition and concentration of gases emitted from combustion equipment such as boilers, furnaces, and other industrial processes. The primary purpose is to assess the efficiency of the combustion process and to monitor . Testo 327-1 – Flue Gas Analyser (Advanced Set) The Testo 327-1 Flue Gas Analyser is a portable introductory instrument for measuring combustion efficiency and flue gas parameters such as O2, CO2, CO and flue draught. It features an easy-to-read 4 line LED display with background lighting for readability in various lighting conditions. The .

Meaning you can get the most out of your appliances and you don’t have to worry about interruptions to your business. . Flue gas analyser calibration is essential in order to ensure fully accurate readings to keep yours and your customers’ appliances and the environments they’re in safe. If you suspect your devices aren’t up to .Flue Gas Analysis in Industry. 3 1. Foreword 5 2. The combustion process 6 2.1 Energy and combustion 6 2.2 Combustion plants 8 2.3 Fuels 9 2.4 Combustion air; excess air value 10Flue gas is very hot and humid as can be seen from the pluming on cold days as the warm flue gas hits the cold air. This pluming is the water vapour in the flue gas condensing as it hits the cold air forming water droplets. Pulling a hot, humid gas sample into an electronic piece of instrumentation can cause

#EngineeringChemistry #inTamil #Firstyear #1stSemester #AnnaUniversity #ChemistryTrending #ORSAT SUBSCRIBE the channel for FIVE Units Notes Here http://bit.

flue gas analysis pdf

two prong ph tester moisture meter

WEB28 de jul. de 2022 · https://fapello.com/anitta/ https://fapello.com/mc-mirella/ https://fapello.com/vanessa-vailatti/ https://fapello.com/juliana-bonde/ .

flue gas analysis meaning|sorbothane temperature efficiency chart